Laser Cutting

Trinity Brand Industries uses the highest quality IPG fiber optic laser equipment to provide customers with the precision and reliability required to meet your custom shim requirements. We specialize in laser cutting extremely thin gauge materials starting with .0005” up to .250” thick. With over 30 years of supplying thin gauge precision metals to the industrial market, this offers us the unique position of having a vast inventory for our laser fabrication clientele. Our customers that require laser cutting can choose from a wide variety of materials in stainless (301,302,304,316,430,17-4 and more) brass, bronze, copper, aluminum, cold rolled steel, high carbon steel, and titanium. We can also offer adhesive backed custom laser cut metals upon request. All materials are purchased from USA sources, made to aerospace specs, and come with Material test reports/mill certifications. This extensive inventory allows TBI to offer your custom laser shims in the quickest turnaround time possible, whether it’s a one-piece prototype or a higher volume production run, we can do it! Quick, Precise, Reliable.

Waterjet Cutting

Using the latest Waterjet Cutting equipment we can cut intricate parts from metal, plastic, rubber, composites, ceramics and glass. Our equipment has a continuous 87,000 psi pressure which delivers more cutting power to increase production and lower costs. Perfect for aerospace, automotive, or any fabrication requiring superior edge quality.

Stamping

We provide a broad range of presses to produce all types of materials and shapes. Our full-service Tool Room can build the most intricate tooling to provide our customers with a complete finished product. We also offer secondary forming operations, as well as value-added heat treating and plating.

Wire EDM

Wire EDM allows us to maintain the tightest tolerances to produce the highest quality metal tools and components where accuracy and precision is required. Typically used for making dies, fixtures, and precision tooling where superior quality is required for the most complex geometries.

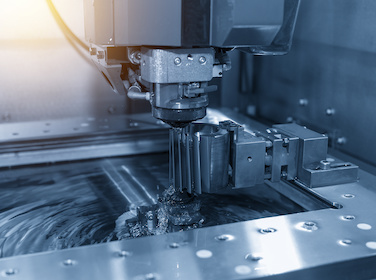

CNC Machining Centers

Whether you require turning or milling, our CNC equipment and expertise can provide a finished part manufactured to your exact specs from your CAD drawings. We can offer assistance with product development for prototype or production parts for virtually any material. Using our CNC equipment along with our full-service Tool Room, we can also create complete dies and molds to your exact specifications.

3D Industrial Printing

This new and exciting technology has opened up many industrial applications in Aerospace, Medical, Automotive, and Architecture applications to name a few. We offer complete design services along with rapid prototyping for quick product development and the capability to provide finished 3D solid parts from your digital file. We use the highest quality materials in our process- Stainless, Aluminum, Titanium, Plastic, and Nylon, and more.